【Product Overview】

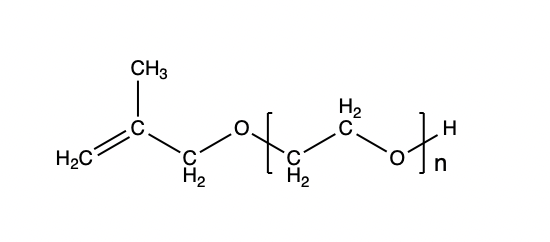

Methyl allyl polyoxyethylene glycol ether is polymerized from methyl allyl alcohol and ethylene oxide, with the chemical formula: CH2=C(CH3)CH2O(CH2CH2O)nH, It is the main raw material for polycarboxylate based high-performance water reducers. The synthesized polycarboxylate based high-performance water reducers have the characteristics of high water reduction rate and wide adaptability, and are suitable for pumping concrete, high-strength concrete, high fluidity concrete, etc.

【Molecular structure】

【Product Features】

◆ This series of products adopts internationally advanced alkoxylation devices, catalytic processes, and production technologies, with a narrow molecular weight distribution, low diol content, and high double bond retention rate;

◆ The synthesized polycarboxylate superplasticizer has the characteristics of low dosage, high water reduction rate, good reinforcement effect, durability, non rusting of steel bars, and environmental friendliness;

◆ Ideal copolymers can be formed with unsaturated monomers such as acrylic acid and maleic anhydride to prepare high-performance polycarboxylate superplasticizers with different properties;

◆ This series of products is non-toxic, non irritating, has good water solubility, will not hydrolyze or deteriorate, and has good compatibility with various components.

【Product indicators】

|

Model name |

HLP-330A |

HLP-330L |

HLP-330S |

|

Appearance |

Colorless to pale yellow liquid |

Colorless to pale yellow liquid |

White flakes |

|

pHvalue(1%Aqueous solution) |

K±1.0 |

K±1.0 |

K±1.0 |

|

Hydroxyl value(以KOH计),mg/g |

22.0-25.0 |

22.0-25.0 |

22.0-25.0 |

|

Double bond retention rate,%≥ |

93.0 |

93.0 |

93.0 |

|

Solid content,% |

60.0-61.0 |

/ |

/ |

|

Chroma,Hazen≤ |

50.0 |

50.0 |

/ |

【Purpose】

◆ Mainly suitable for the synthesis of water reducing polycarboxylate superplasticizers.

【Usage method】

◆ Polyether is used as a major monomer and polymerized with unsaturated small monomers such as acrylic acid and maleic anhydride in an oxidation-reduction initiation system to synthesize polycarboxylate superplasticizer.

【Packaging and storage】

◆ Liquid products are transported in bulk by tank trucks; The sheet is packaged in a 25kg woven bag;

◆ This product is non-toxic and flame retardant, and can be transported according to general chemical transportation regulations. It should be stored in a dry and ventilated place, away from sunlight and rain, and kept away from fire and heat sources. Under normal temperature storage conditions, the shelf life of this product is 6 months.

【Matters needing attention】

◆ Ingestion may cause harm to the human body. If ingested, immediately drink a large amount of warm water to induce vomiting and seek medical attention.

◆ Mild irritation to the eyes, skin, and mucous membranes. In case of accidental contact with the eyes, rinse immediately with water and seek medical attention. In case of skin contact, rinse immediately with water.

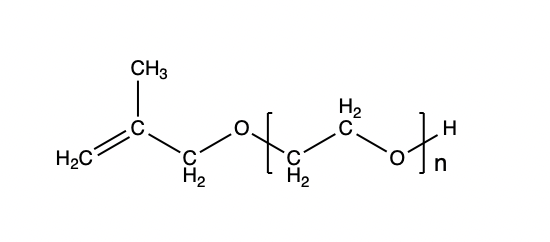

【Product Overview】

Methyl allyl polyoxyethylene glycol ether is polymerized from methyl allyl alcohol and ethylene oxide, with the chemical formula: CH2=C(CH3)CH2O(CH2CH2O)nH, It is the main raw material for polycarboxylate based high-performance water reducers. The synthesized polycarboxylate based high-performance water reducers have the characteristics of high water reduction rate and wide adaptability, and are suitable for pumping concrete, high-strength concrete, high fluidity concrete, etc.

【Molecular structure】

【Product Features】

◆ This series of products adopts internationally advanced alkoxylation devices, catalytic processes, and production technologies, with a narrow molecular weight distribution, low diol content, and high double bond retention rate;

◆ The synthesized polycarboxylate superplasticizer has the characteristics of low dosage, high water reduction rate, good reinforcement effect, durability, non rusting of steel bars, and environmental friendliness;

◆ Ideal copolymers can be formed with unsaturated monomers such as acrylic acid and maleic anhydride to prepare high-performance polycarboxylate superplasticizers with different properties;

◆ This series of products is non-toxic, non irritating, has good water solubility, will not hydrolyze or deteriorate, and has good compatibility with various components.

【Product indicators】

|

Model name |

HLP-330A |

HLP-330L |

HLP-330S |

|

Appearance |

Colorless to pale yellow liquid |

Colorless to pale yellow liquid |

White flakes |

|

pHvalue(1%Aqueous solution) |

K±1.0 |

K±1.0 |

K±1.0 |

|

Hydroxyl value(以KOH计),mg/g |

22.0-25.0 |

22.0-25.0 |

22.0-25.0 |

|

Double bond retention rate,%≥ |

93.0 |

93.0 |

93.0 |

|

Solid content,% |

60.0-61.0 |

/ |

/ |

|

Chroma,Hazen≤ |

50.0 |

50.0 |

/ |

【Purpose】

◆ Mainly suitable for the synthesis of water reducing polycarboxylate superplasticizers.

【Usage method】

◆ Polyether is used as a major monomer and polymerized with unsaturated small monomers such as acrylic acid and maleic anhydride in an oxidation-reduction initiation system to synthesize polycarboxylate superplasticizer.

【Packaging and storage】

◆ Liquid products are transported in bulk by tank trucks; The sheet is packaged in a 25kg woven bag;

◆ This product is non-toxic and flame retardant, and can be transported according to general chemical transportation regulations. It should be stored in a dry and ventilated place, away from sunlight and rain, and kept away from fire and heat sources. Under normal temperature storage conditions, the shelf life of this product is 6 months.

【Matters needing attention】

◆ Ingestion may cause harm to the human body. If ingested, immediately drink a large amount of warm water to induce vomiting and seek medical attention.

◆ Mild irritation to the eyes, skin, and mucous membranes. In case of accidental contact with the eyes, rinse immediately with water and seek medical attention. In case of skin contact, rinse immediately with water.